Effortless Packaging Solutions: Intelligent Automatic Box Gluing Machines

May 19,2025

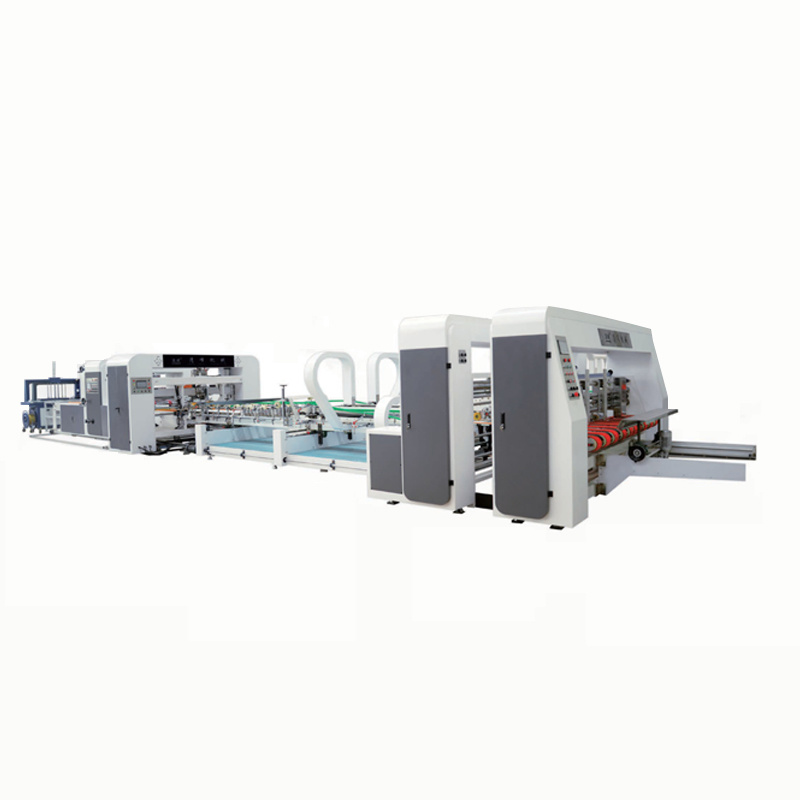

Effortless Packaging Solutions: Intelligent Automatic Box Gluing Machines

Introduction to Intelligent Automatic Box Gluing Machines

The packaging industry is continually evolving, with innovations aimed at improving efficiency and reducing labor costs. **Intelligent automatic box gluing machines** represent a significant leap forward in this evolution. These machines streamline the packaging process, offering businesses a way to enhance productivity while maintaining high-quality standards. In this article, we explore the features, benefits, applications, and future of intelligent automatic box gluing machines, ensuring that you understand their vital role in modern packaging solutions.

Understanding Automatic Box Gluing Machines

Automatic box gluing machines are specialized devices designed to automate the process of gluing boxes together. They are equipped with the latest technology to perform tasks such as folding, gluing, and sealing boxes swiftly and accurately.

The Mechanism Behind Automatic Box Gluing Machines

These machines operate using a combination of mechanical and electronic components. They typically include a **gluing station**, where adhesive is applied to box flaps, and a **pressing station**, where the glued flaps are held together until the adhesive sets. Some advanced models are equipped with sensors to detect box dimensions and adjust the gluing process accordingly, ensuring a perfect fit every time.

Key Features of Intelligent Automatic Box Gluing Machines

1. **High Speed and Efficiency**: Capable of producing hundreds of boxes per hour, these machines significantly reduce production time.

2. **Precision Gluing**: Advanced technology ensures that glue is applied consistently, minimizing waste and ensuring a strong bond.

3. **User-Friendly Interface**: Many models come with touchscreen controls that allow for easy operation and adjustments.

4. **Versatility**: Suitable for various box types, including regular slotted containers (RSC), die-cut boxes, and custom designs.

5. **Low Maintenance**: Designed for durability, these machines require minimal maintenance, reducing downtime.

The Benefits of Using Intelligent Automatic Box Gluing Machines

Adopting intelligent automatic box gluing machines offers numerous advantages for businesses in the packaging sector.

1. Increased Productivity

By automating the gluing process, businesses can significantly increase their output. This efficiency allows companies to meet growing demand without sacrificing quality.

2. Cost Reduction

Automating repetitive tasks reduces labor costs and minimizes human error, leading to fewer defects and less material waste.

3. Enhanced Quality Control

With precise gluing and consistent quality, these machines help in maintaining high standards, which translates to better customer satisfaction.

4. Flexibility and Customization

Intelligent automatic box gluing machines can be easily adjusted for different box sizes and styles, providing businesses with the flexibility to meet diverse packaging needs.

5. Sustainability Advantages

Many modern machines use adhesive systems that are environmentally friendly, contributing to more sustainable packaging practices.

Applications of Intelligent Automatic Box Gluing Machines

These machines find applications across various industries, including:

1. E-commerce Packaging

With the rise of online shopping, efficient packaging solutions are critical for e-commerce businesses. Intelligent automatic box gluing machines ensure that products are securely packed for shipping, minimizing damage during transit.

2. Food and Beverage Industry

Packaging for food products requires strict adherence to hygiene standards. Automatic gluing machines offer a sanitary method of sealing boxes, ensuring food safety.

3. Pharmaceuticals

In the pharmaceutical sector, packaging integrity is paramount. These machines help create secure packaging that maintains product safety and compliance with regulatory standards.

4. Retail Packaging

Retail packaging often requires visually appealing designs. Automatic gluing machines can produce custom boxes that enhance brand presentation, aiding in marketing efforts.

5. Electronics Packaging

Protecting delicate electronic components is vital. Intelligent gluing machines produce robust boxes that shield products from damage during shipping and handling.

Choosing the Right Intelligent Automatic Box Gluing Machine

When selecting an automatic box gluing machine, businesses should consider several factors:

1. Production Volume

Evaluate the expected production volume to determine the machine’s speed and capacity requirements.

2. Box Types and Sizes

Ensure the machine can accommodate the various box designs, sizes, and materials your business uses.

3. Budget Constraints

While it’s important to invest in quality machinery, ensure that it fits within your overall budget.

4. Support and Maintenance

Choose a manufacturer that offers reliable customer support and maintenance services, ensuring minimal downtime.

5. Technology and Features

Look for machines equipped with advanced technology, such as sensors and automation features, to enhance usability and efficiency.

The Future of Intelligent Box Gluing Technology

As technology continues to advance, the future of intelligent automatic box gluing machines looks promising. We anticipate several trends that will shape the industry:

1. Smart Integration

Future machines will increasingly integrate with other production line technologies for streamlined operations and real-time monitoring.

2. Enhanced Automation

With the rise of Industry 4.0, machines will incorporate artificial intelligence and machine learning to optimize gluing processes and predictive maintenance.

3. Sustainability Focus

The move towards eco-friendly packaging is likely to drive innovation in materials and adhesive technologies, making packaging more sustainable.

4. Customization Capabilities

As consumer preferences evolve, machines will adapt to offer more customized packaging solutions that cater to specific market demands.

5. Remote Monitoring

Future machines may offer remote monitoring capabilities, allowing operators to oversee performance and troubleshoot issues from anywhere.

Frequently Asked Questions (FAQs)

1. What types of boxes can be processed using automatic box gluing machines?

Automatic box gluing machines can handle various box types, including regular slotted containers, die-cut boxes, and custom-designed packaging.

2. How do I maintain an automatic box gluing machine?

Regular maintenance includes cleaning the glue applicators, checking for wear on mechanical parts, and ensuring the electrical components are functioning properly.

3. Can these machines handle different adhesive types?

Yes, many intelligent automatic box gluing machines are designed to work with various adhesive types, including hot melt, cold glue, and water-based adhesives.

4. What is the average speed of an automatic box gluing machine?

The speed can vary significantly based on the model, but many machines can produce between 20 to 100 boxes per minute.

5. Are automatic box gluing machines suitable for small businesses?

Absolutely! There are models available that cater to small production runs, making them suitable for businesses of all sizes looking to improve efficiency.

Conclusion

In today's fast-paced packaging industry, **intelligent automatic box gluing machines** stand out as a transformative solution. Their ability to enhance productivity, reduce costs, and maintain high-quality standards makes them an indispensable asset for businesses across various sectors. As technology continues to evolve, these machines promise even greater efficiency and sustainability, ensuring that your packaging processes remain competitive and effective. By embracing these intelligent solutions, businesses can not only streamline their operations but also meet the demands of a dynamic market landscape.

Contact Us

E-mail :

evallp@VIP.163.com

Phone/WhatsApp:

+86-15030750375

Address:

West Side of Youyou Road, Dongguang Town, Dongguang County, Cangzhou City, Hebei Province