Effortlessly Handle Complex Packaging Tasks with an Automatic Lower Folding and Gluing Machine

Jun 13,2025

Effortlessly Handle Complex Packaging Tasks with an Automatic Lower Folding and Gluing Machine

Table of Contents

- 1. Introduction to Automatic Lower Folding and Gluing Machines

- 2. Benefits of Using an Automatic Lower Folding and Gluing Machine

- 3. Key Features to Look For

- 4. Applications in Various Industries

- 5. Comparing Manual vs. Automatic Machines

- 6. Maintenance Tips for Optimal Performance

- 7. Return on Investment: Understanding the Cost-Effectiveness

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Automatic Lower Folding and Gluing Machines

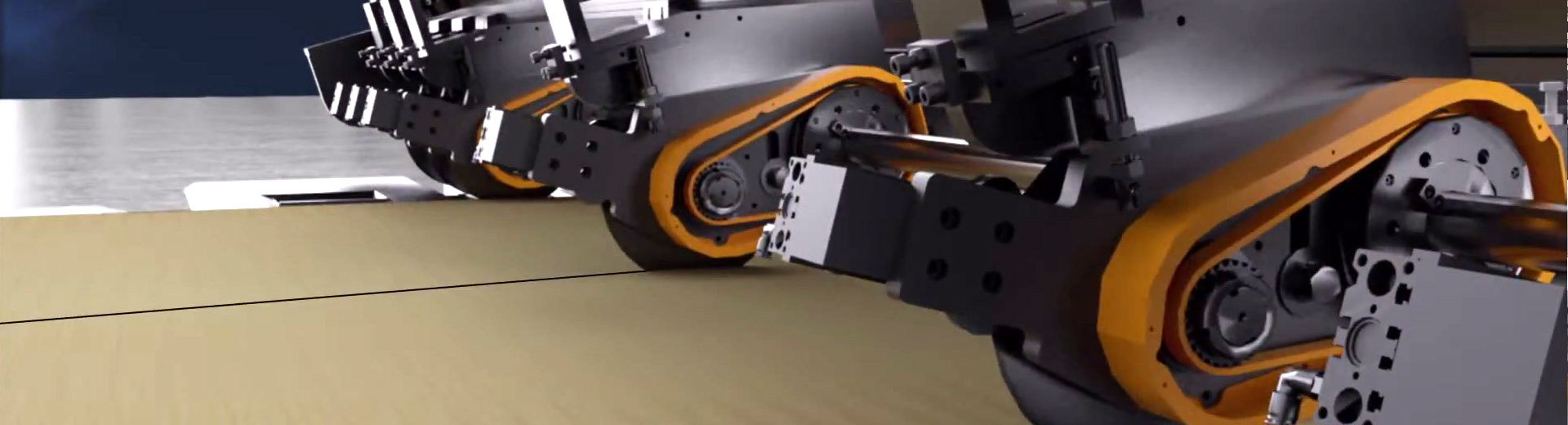

In today's fast-paced packaging industry, efficiency and precision are paramount. An **automatic lower folding and gluing machine** is designed to streamline the packaging process, allowing businesses to handle complex tasks effortlessly. This machine automates the folding and gluing process, reducing the need for manual labor and minimizing errors, ultimately leading to a more efficient production line.

2. Benefits of Using an Automatic Lower Folding and Gluing Machine

Adopting an automatic lower folding and gluing machine comes with numerous advantages, including:

Enhanced Efficiency

These machines significantly speed up the packaging process, allowing businesses to meet high demand without compromising quality. By automating repetitive tasks, companies can allocate labor to more strategic roles.

Cost Reduction

While the initial investment may seem high, the long-term savings from reduced labor costs and increased output make these machines a cost-effective solution. They help in minimizing wastage and improving the overall profitability of packaging operations.

Precision and Consistency

Automatic machines are designed for accuracy, ensuring that every fold and glue application is consistent. This level of precision is crucial for maintaining product quality and brand reputation.

Versatility

These machines can handle a variety of materials and packaging styles, making them suitable for different industries and products. This versatility allows businesses to adapt quickly to market changes.

3. Key Features to Look For

When considering an automatic lower folding and gluing machine, certain features are essential to ensure you choose the right equipment for your needs:

Speed and Capacity

Evaluate the machine’s speed and capacity, ensuring it meets your production requirements. A higher output per hour can lead to significant time savings.

Material Compatibility

Check the types of materials the machine can work with, including cardboard, corrugated board, and other packaging materials. This feature will determine the machine's versatility.

Easy Setup and Operation

Look for machines that are user-friendly, with intuitive controls and easy setup processes. This feature reduces training time and enhances productivity.

Durability and Maintenance

Choose a machine made from high-quality materials that can withstand continuous use. Additionally, consider machines that require minimal maintenance to keep operational costs low.

4. Applications in Various Industries

The versatility of automatic lower folding and gluing machines makes them suitable for various industries, including:

Food and Beverage

In the food industry, these machines are essential for packaging items like boxes for snacks, beverages, and other consumables that require hygienic packaging.

Cosmetics and Pharmaceuticals

Cosmetic and pharmaceutical products often demand intricate packaging solutions for branding and consumer safety. Automatic machines ensure these packages are folded and glued with precision.

Electronics

Packaging for electronics needs to be robust and protective. An automatic machine can efficiently create sturdy boxes that keep products safe during transit.

Retail and E-commerce

As e-commerce continues to grow, the demand for efficient packaging solutions increases. Automatic gluing machines help businesses quickly fulfill orders, enhancing customer satisfaction.

5. Comparing Manual vs. Automatic Machines

When deciding between manual and automatic lower folding and gluing machines, consider the following factors:

Labor Requirements

Manual machines require more labor, leading to higher labor costs and greater potential for human error. Automatic machines reduce labor needs significantly.

Time Efficiency

Automatic machines can complete tasks much faster than manual methods, allowing businesses to increase output and meet tight deadlines.

Quality Control

Automatic machines provide consistent quality and reduce the likelihood of defects, making them a safer choice for businesses focused on brand integrity.

6. Maintenance Tips for Optimal Performance

To keep your automatic lower folding and gluing machine operating at peak efficiency, follow these maintenance tips:

Regular Cleaning

Dust and adhesive residue can accumulate, affecting performance. Regularly clean the machine to ensure it functions smoothly.

Routine Inspections

Schedule routine inspections to identify and address potential issues before they become significant problems. This proactive approach can extend the machine's lifespan.

Adhesive Quality

Use high-quality adhesives as specified by the manufacturer. Poor-quality adhesives can compromise the effectiveness of the gluing process.

7. Return on Investment: Understanding the Cost-Effectiveness

Investing in an automatic lower folding and gluing machine may require substantial initial capital. However, businesses should consider the long-term benefits:

Increased Output

Higher production rates contribute to faster order fulfillment, enabling businesses to take on more clients and increase revenue.

Reduced Labor Costs

By minimizing the need for manual labor, companies can save significantly on labor expenses, allowing them to allocate resources elsewhere.

Improved Quality Control

With enhanced precision, businesses experience fewer errors, reducing waste and increasing overall profitability.

8. Conclusion

An **automatic lower folding and gluing machine** is a valuable asset for any business looking to enhance its packaging operations. With its ability to improve efficiency, reduce costs, and maintain quality, this technology is essential for staying competitive in today's market. By understanding the features, benefits, and applications of these machines, companies can make informed decisions that contribute to their success.

9. Frequently Asked Questions

1. What types of products can be packaged using an automatic lower folding and gluing machine?

These machines are versatile and can package a wide range of products, including food items, cosmetics, electronics, and retail goods.

2. How much does an automatic lower folding and gluing machine cost?

The cost varies based on features, speed, and brand, but investing in a high-quality machine can lead to significant long-term savings.

3. Are these machines easy to operate?

Yes, most automatic machines are designed for user-friendliness, requiring minimal training for operators.

4. How often should I maintain my machine?

Regular maintenance is crucial. A routine check-up every few months, along with daily cleaning, can help ensure optimal performance.

5. Can these machines accommodate different packaging sizes?

Yes, many automatic lower folding and gluing machines are designed to handle various sizes and types of packaging, offering versatility for different products.

Investing in an automatic lower folding and gluing machine can be a game-changer for businesses seeking to enhance their packaging processes. The combination of efficiency, cost-effectiveness, and quality makes these machines indispensable in today's competitive landscape.

Contact Us

E-mail :

evallp@VIP.163.com

Phone/WhatsApp:

+86-15030750375

Address:

West Side of Youyou Road, Dongguang Town, Dongguang County, Cangzhou City, Hebei Province