Transform Your Packaging Process with an Automated Lower Folding and Gluing Machine

Jun 23,2025

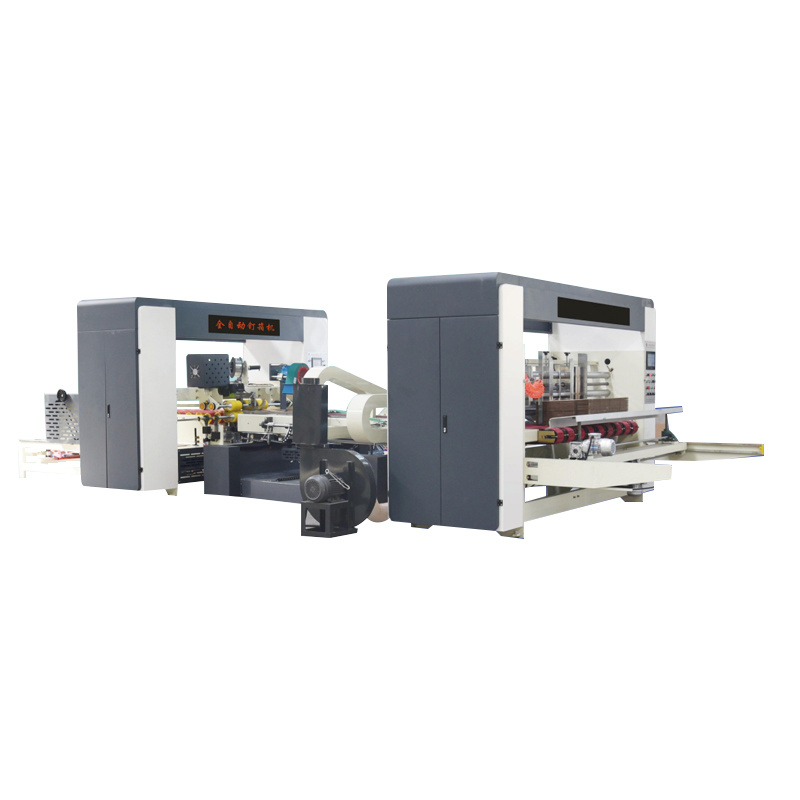

Transform Your Packaging Process with an Automated Lower Folding and Gluing Machine

Understanding the Role of Automation in Packaging

In today's fast-paced market, **automation** has become a cornerstone in revolutionizing various industries, especially in **packaging**. The integration of automated systems not only streamlines the workflow but also enhances productivity and reduces overall costs. One of the most impactful innovations in this field is the **automated lower folding and gluing machine**. This machine effectively addresses the increasing demand for efficiency and precision in packaging processes.

Benefits of Using an Automated Lower Folding and Gluing Machine

1. Enhanced Efficiency and Speed

Automated lower folding and gluing machines significantly **improve operational efficiency**, allowing businesses to process a greater volume of products in less time. By automating repetitive tasks, companies can achieve faster turnaround times, which is crucial in meeting tight deadlines and customer demands.

2. Consistent Quality Control

Maintaining consistent quality is essential in packaging. Automated machines ensure precise folds and glue applications, minimizing human error. This consistency is vital in maintaining the integrity of the packaging, leading to higher customer satisfaction and reduced returns.

3. Cost Reduction

While the initial investment in an automated system may seem substantial, the long-term savings are undeniable. Reduced labor costs, lower material waste, and minimized errors contribute to significant savings over time. Businesses can reinvest these savings into other areas to foster growth.

4. Versatility in Packaging Solutions

Automated lower folding and gluing machines offer flexibility in terms of the types of packaging they can handle. From boxes to cartons, these machines can be adjusted to accommodate various sizes and styles, making them suitable for diverse products.

5. Improved Safety and Ergonomics

By automating the folding and gluing processes, the risk of workplace injuries associated with manual labor decreases. Automated solutions reduce the physical strain on employees, promoting a safer and more ergonomic working environment.

Key Features of Automated Lower Folding and Gluing Machines

1. Advanced Technology Integration

Modern automated machines come equipped with advanced technologies such as **PLC control systems** and **sensor-driven feedback systems**. These features enhance the machine's operational reliability and allow for real-time monitoring and adjustments.

2. User-Friendly Interface

A key feature of automated systems is their intuitive user interface. Operators can easily set parameters, monitor performance, and make adjustments with minimal training, reducing the learning curve and improving operational efficiency.

3. Quick Changeover Capabilities

In industries where product variability is high, quick changeover capabilities are essential. Automated machines enable rapid transition between different packaging formats, minimizing downtime and maximizing productivity.

4. Energy Efficiency

With growing environmental concerns, energy-efficient machines are in demand. Many automated lower folding and gluing machines are designed to minimize energy consumption while maintaining high performance, making them a sustainable choice.

How to Choose the Right Automated Lower Folding and Gluing Machine

When selecting an automated lower folding and gluing machine, several factors should be considered to ensure that it meets your specific needs.

1. Assess Your Production Volume

Evaluate your average production volume to determine the machine's capacity requirements. Higher volumes necessitate machines that can handle increased speeds without compromising quality.

2. Understand Your Packaging Requirements

Consider the types of packaging you need. Different machines may be better suited for specific materials, sizes, or styles. Ensure that the machine you choose aligns with your packaging needs.

3. Budget Considerations

While it's crucial to invest in quality machinery, staying within budget is also essential. Compare the features and costs of different machines to find the best value for your investment.

4. Manufacturer Reputation and Support

Select a reputable manufacturer known for quality and reliable support. A strong service network ensures that you receive help with installation, maintenance, and troubleshooting when needed.

Implementing the Automated System in Your Packaging Line

Introducing an automated lower folding and gluing machine into your packaging line requires careful planning and execution.

1. Conduct a Needs Assessment

Before implementation, assess your current processes to identify areas that can benefit from automation. Understanding your workflow will help in tailoring the transition to meet your specific needs.

2. Train Your Staff

Ensure that your team is equipped with the necessary skills to operate the new machine. Comprehensive training will facilitate a smoother integration and minimize disruptions during the transition.

3. Monitor Performance Post-Implementation

After installation, closely monitor the machine's performance. Collect data on production speed, quality control, and downtime to assess the impact of the new system and identify areas for improvement.

Future Trends in Packaging Automation

The landscape of packaging automation is constantly evolving, with several emerging trends that businesses should be aware of.

1. Increased Use of Artificial Intelligence

The integration of **AI** in packaging automation is anticipated to grow. AI can enhance predictive maintenance, optimize workflows, and improve quality assurance processes.

2. Smart Packaging Solutions

Smart technologies, including IoT-enabled devices, are transforming packaging. These innovations allow for real-time data collection and analysis, enabling businesses to make informed decisions and enhance efficiency.

3. Sustainable Packaging Practices

The demand for sustainable packaging solutions is on the rise. Automated machines are being designed to work with eco-friendly materials, aligning with consumer preferences for greener products.

FAQs About Automated Lower Folding and Gluing Machines

1. What is the average cost of an automated lower folding and gluing machine?

The cost varies widely based on features and capacities but typically ranges from **$50,000 to $150,000**.

2. How long does it take to install an automated machine?

Installation can take anywhere from **a few days to a couple of weeks**, depending on the machine's complexity and the existing setup.

3. What maintenance is required for these machines?

Regular maintenance includes cleaning components, checking for wear and tear, and calibrating settings to ensure optimal performance.

4. Can these machines handle different types of materials?

Yes, many automated lower folding and gluing machines are designed to handle various materials, including cardboard, paper, and some plastics.

5. How can I ensure a smooth transition to automation?

Conduct thorough training for staff, assess current workflows, and monitor performance regularly to ensure a seamless integration process.

Conclusion

Incorporating an **automated lower folding and gluing machine** into your packaging process can significantly enhance efficiency, quality, and cost-effectiveness. By understanding the benefits, key features, and implementation strategies, businesses can make informed decisions that align with their operational goals. As packaging automation continues to evolve, staying ahead of trends and technologies will be crucial in maintaining a competitive edge in the market. Embrace automation today, and transform your packaging process for tomorrow’s demands.

Contact Us

E-mail :

evallp@VIP.163.com

Phone/WhatsApp:

+86-15030750375

Address:

West Side of Youyou Road, Dongguang Town, Dongguang County, Cangzhou City, Hebei Province